Products

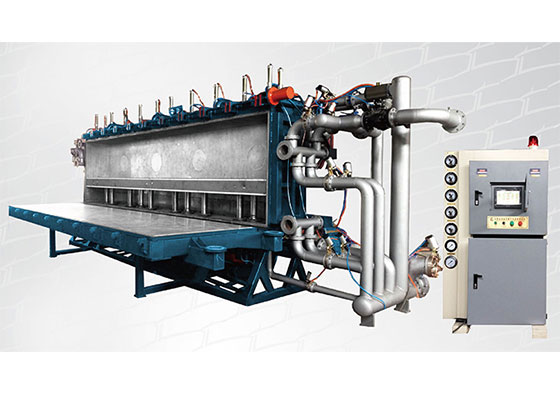

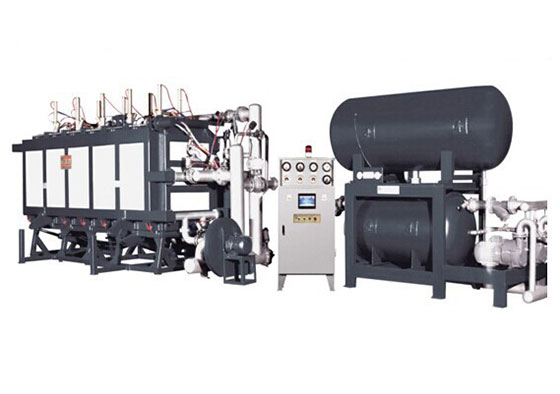

1.This machine applies PLC controller and touch screen control system to finish the autocycle process of opening-closing mould,feeding,heating,heat preservation,cooling,demoulding and releasing.

2.This machine is welded by high quality square profile steel and steel plate,which is subjected to heat treatment toensure the machine has no deformation,and has high durability after being assembled.

3.This machine applies unique and advanced EPS heat penetration process,which make high quality plates whose six faces and interior are the same perfect,It also reaches remarkable energy saving effect.

4.Advanced EPS heat penetration technique,reasonable pipeline system and unique design construction,which improve productivity,and make this machine leading in domestic EPS industry.

5.Most of the main components are of world-famous brand,with reliable performance,stable quality,long service life and low maintenance cost.

6.This machine applies hydraulic pressure transmission,hydraulic ingot stripping,it makes steady running and tight locking.

7.High production efficiency.The production cycle of each plate is 4-8min.Automatic pneumatic charging shorten the production time.

8.The height ofthe inner dimension can be adjusted from 800-1270mm.