News

2021-04-21

In recent years, because of its advantages in energy saving, emission reduction, and environmental protection, the warm asphalt mixing technology has attracted wide attention from insiders at home and abroad. As a domestic professional manufacturer of asphalt mixing equipment, Tietuo Machinery has never stopped paying attention to and exploring environmental technologies such as warm asphalt mixing and asphalt recycling. Tietuo Machinery has independently developed the TWB series of asphalt warm mixing equipment in combination with the current characteristics of China's pavement asphalt production.

It is understood that the current mixing of warm-mix asphalt mixtures at home and abroad is usually achieved in four different ways, namely: asphalt-mineral method, emulsified asphalt warm-mixing method (warm mixing agent), organic additive method, foamed asphalt warm-mixing method . In China, the emulsified asphalt warm mixing method and organic additive method are more commonly used, that is, adding Evotherm warm mixing agent or Sasobit warm mixing agent to achieve warm mixing when mixing the asphalt mixture. The TWB series asphalt warm mixing device independently developed by Tietuo Machinery adopts the foamed asphalt warm mixing method.

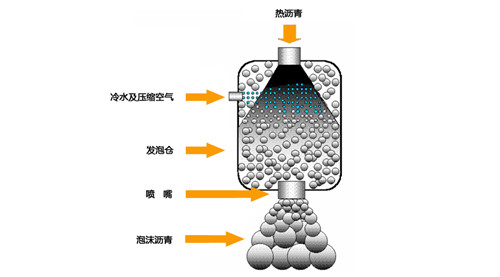

The foamed asphalt warm mixing method is to add a certain proportion of water to the high-temperature asphalt during the production process of the normal hot-mix asphalt mixture to rapidly expand the volume of the asphalt to produce foamed asphalt. The material is mixed into an asphalt mixture. Foamed asphalt has lower viscosity than asphalt and increased workability. It can fully coat aggregate at a lower temperature, thereby reducing the mixing temperature of the asphalt mixture and realizing the production of foamed asphalt warm mix. Compared with the warm mixing method that requires the addition of a warm mixing agent, the warm mixing method that only adds water is obvious in terms of saving the production cost of the asphalt mixture.

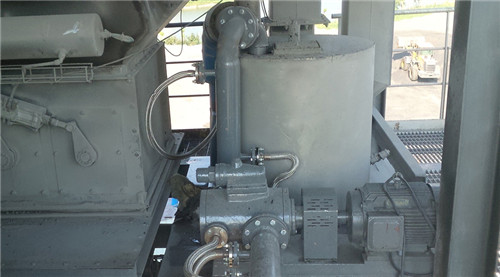

Application examples of TWB asphalt foaming warm mixing equipment series:

温拌沥青混合料与普通沥青混合料对比

The TWB series of asphalt foaming warm mixing equipment not only meets the requirements of cooling the plant-mixed asphalt mixture by 30°C under standard conditions, but also has no harmful gases during production and paving. At the same time, it has the following characteristics:

1. Modular design, fast installation, convenient hoisting, equipment installation and debugging can be completed within half a day;

2. Green and environmental protection, low investment and does not affect the original finished product mix ratio. Using water as the foaming medium does not affect the mix ratio of the original finished materials, and the customer input is small, and the effect is significant;

3. With one-key switching, the realization of warm mixing and hot mixing does not interfere with each other.

4. Easy to use and easy to understand, with low failure. In the design of the operation panel and control system of the TWB series, the convenience of operation and humanized operation are fully considered, which is easy to learn and understand. The main components are all high-profile foreign industries, such as the use of American diaphragm pumps, which has a low failure rate;

5. Fully automated control. The TWB series equipment is equipped with multiple water level, water temperature and other sensors, which feedback and automatically regulate production at all times. If there is a failure, it can promptly alarm and remind;

6. Micro-foam asphalt improves the quality of the mixture and reduces the difficulty of construction. The micro-foamed asphalt produced by the foaming of TWB series equipment can effectively improve the uniformity of mixing and reduce the difficulty of subsequent paving and rolling construction links. (This article comes from Tietuo Machinery)